From Ancient Art to Modern Science

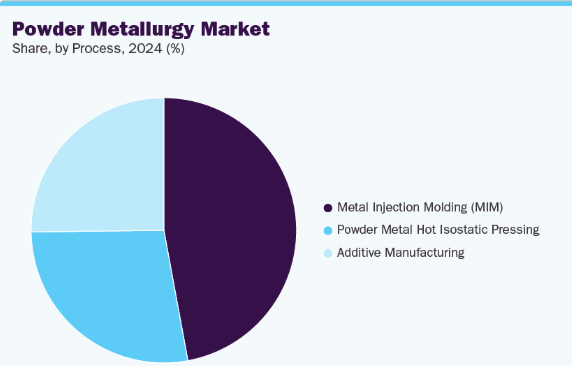

The story of powder metallurgy (PM) is one of remarkable evolution. What began millennia ago with the hammering of gold and platinum powders by ancient civilizations has transformed into one of the most sophisticated and sustainable manufacturing philosophies of the 21st century. Today, PM is not merely a process of compacting and sintering metal powder; it is a pinnacle of materials science, integrating advanced techniques like Metal Injection Moulding (MIM) and Additive Manufacturing (AM) to solve the most complex engineering challenges. This report explores how this granular revolution is driving innovation across pivotal global sectors, underpinned by relentless research, a commitment to sustainability, and a shift towards intellectual property as the core of competitive advantage.

The Automotive Engine: Driving Efficiency in a 92.5-Million-Unit Market

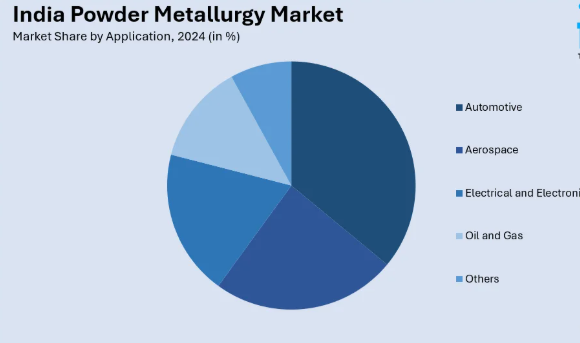

The automotive sector, producing approximately 92.5 million units globally in 2024, stands as the largest consumer of powder metallurgy components. PM is the invisible workhorse within modern vehicles, manufacturing hundreds of high-precision, high-strength parts such as engine connecting rods, transmission gears, oil pump rotors, and shock absorber components.

The industry’s dual pivot toward lightweighting and electrification has dramatically elevated PM’s role. For electric vehicles (EVs), PM enables the creation of complex, durable, and lightweight components essential for efficiency and performance. Critical parts like magnetic cores for electric motors, intricate gear sets for reducers, and porous components for battery systems are increasingly reliant on PM’s design freedom and material conservation. The ability to produce near-net-shape parts with densities exceeding 95% translates directly into extended vehicle range and enhanced power density—key metrics in the EV revolution.

Soaring to New Heights: Aerospace and Medical Devices

Beyond automotive, two sectors exemplify PM’s move into high-value, performance-critical applications: aerospace and medical.

In aerospace, where every gram counts, advanced PM and AM are indispensable. Companies like Boeing and Airbus utilize these technologies to produce components such as fuel nozzles, turbine blades, and structural brackets. These parts are not only lighter than their machined counterparts but often stronger and more heat-resistant, thanks to the fine, homogeneous microstructures achievable through processes like plasma atomization and hot isostatic pressing (HIP). The ability to reduce part count by consolidating multiple assemblies into a single, optimized component further enhances reliability and reduces maintenance.

The medical and dental field represents perhaps the most personalized application of PM. Here, the technology shifts from mass production to mass customization. In orthopedics, PM is used to create biocompatible, porous implants for hips, knees, and spines. This porosity allows for bone ingrowth, creating a biological lock that is more stable and durable than cemented alternatives. In dentistry, the impact is equally transformative. From patient-specific crowns and bridges fabricated via MIM to full dental implant bars produced by AM, PM enables perfect anatomical fit, excellent aesthetics, and rapid turnaround, moving decisively away from one-size-fits-all solutions.

The Sustainable Core: Material Efficiency and the Circular Economy

A compelling, yet often understated, driver of PM’s growth is its inherent alignment with global sustainability goals. In an era focused on the circular economy, PM stands out for its exceptional material efficiency. Unlike traditional subtractive machining, which can waste over 50% of raw material as chips and swarf, PM is an additive-like process. It typically achieves material utilization rates of 95-98%, as most powder is consolidated into the final part.

This dramatic reduction in scrap has profound implications. It lowers raw material consumption, reduces energy use in recycling waste, and minimizes the environmental footprint of manufacturing. This efficiency is increasingly valued in regions with stringent environmental regulations, such as the European Union, making PM a strategically sustainable choice for global manufacturers aiming to meet both cost and ESG (Environmental, Social, and Governance) targets.

Positioned to drive Innovation

The market’s trajectory is unmistakably toward higher complexity and performance. This shift is fueled by continuous technological advancements in powder production and processing. Innovations like gas and plasma atomization produce finer, more spherical metal powders with exceptional flowability and purity, essential for AM and MIM. Concurrently, advances in sintering technologies and post-processing treatments (like surface densification) are delivering parts with mechanical properties that rival, and sometimes exceed, those of wrought materials.

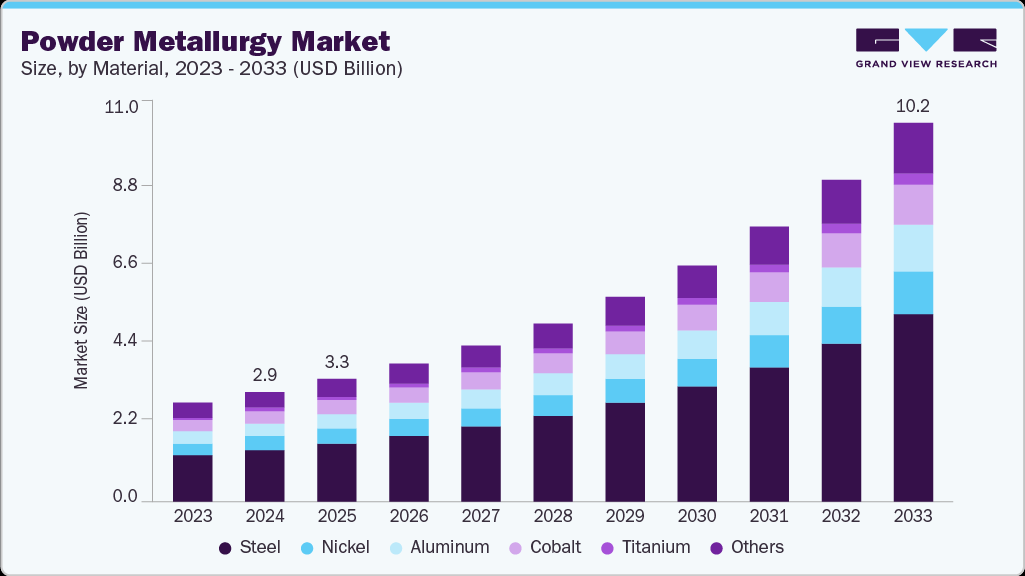

This technological leap is expanding the palette of usable materials far beyond traditional iron and copper. Today, the industry is pioneering the use of high-performance alloys—including nickel-based superalloys for jet engines, titanium alloys for biomedical implants, and specialized aluminum alloys for lightweight automotive structures. Mastering these advanced materials requires deep, fundamental research into powder characteristics, binding mechanisms, and sintering behavior.

Conclusion: PM makers are becoming solution partners

The narrative of powder metallurgy is being rewritten. It is no longer a cost-effective alternative for simple parts but a primary enabler of technological progress across mobility, health, and industrial sustainability. The future of the PM market, particularly for export-oriented hubs like India, will be won not on volume alone but on innovation and intellectual property (IP).

The value chain is moving from component supply to solutions partnership. Success belongs to enterprises that invest in deep R&D to develop proprietary alloy systems, optimize process parameters for emerging materials like graphene-infused powders, and pioneer digital integration of design, simulation, and production. Companies such as Innomet Advanced Materials exemplify this new paradigm. Their focus on advanced ferrous and non-ferrous powder systems and complex design challenges positions them not as mere manufacturers, but as essential innovation partners—turning granular science into monolithic performance for a demanding global market.

In this granular revolution, the most valuable asset is not the powder itself, but the advanced knowledge of how to transform it into the critical components of tomorrow.

#PowderMetallurgy #AdvancedMaterials #ManufacturingInnovation #MetalInjectionMoulding #AdditiveManufacturing #AutomotiveEngineering #ElectricVehicles #AerospaceEngineering #MedicalDevices #DentalTechnology #SustainableManufacturing #CircularEconomy #MaterialEfficiency #Lightweighting #IndustrialInnovation #RAndD #IntellectualProperty #HighPerformanceAlloys #NearNetShape #FutureOfManufacturing #Innomet #Innometadvancedmaterials