A fundamental shift is occurring in the science of exterior coatings. Where “cool” technology once resided primarily in pigment selection, the new frontier lies in the structural engineering of the additive itself. Today’s leading formulations are no longer simple mixtures; they are precisely architected systems where particle design dictates holistic performance—transforming how coatings manage energy, build strength, and ensure longevity.

This evolution responds to a critical industry challenge: moving beyond initial reflectivity to guarantee sustained thermal performance, exceptional film durability, and irrefutable, data-backed superiority. The solution has emerged not from incremental adjustments, but from foundational advances in material science and particle engineering.

Redefining Performance Benchmarks with Hard Data

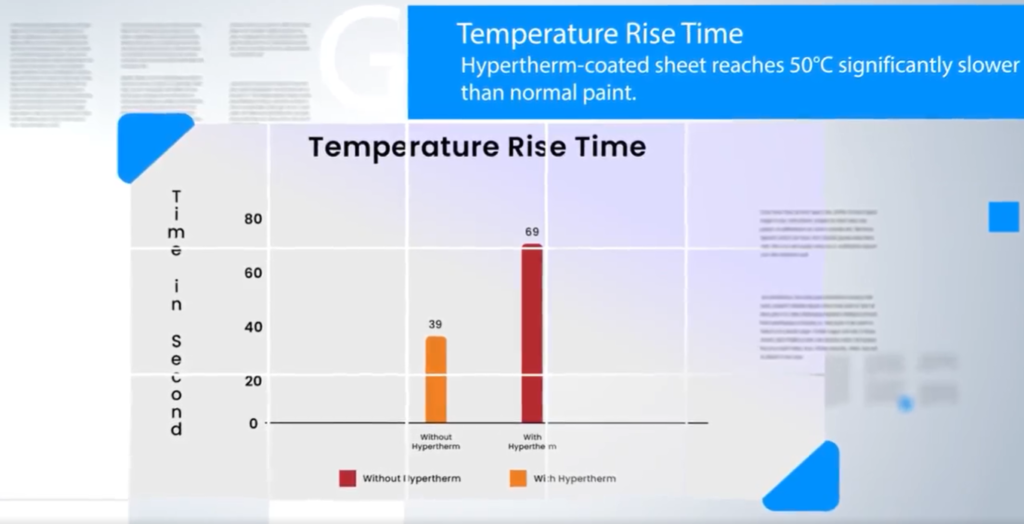

The new standard for cool coatings is defined by measurable differentials. Consider a controlled, side-by-side analysis that illustrates this paradigm shift: a surface coated with a formulation utilizing Hypertherm, a next-generation engineered silicate, achieved a peak temperature 50°C lower than a standard coating under identical infrared exposure.

More revealing than the peak temperature, however, is the kinetics of thermal resistance. While conventional paints exhibited rapid heat penetration in just 39 seconds, the advanced silicate formulation dramatically slowed the process, delaying significant heat buildup for 69 seconds. This 77% increase in thermal resistance time is a critical metric. It signals a coating that doesn’t merely reflect heat but actively impedes its transfer—a decisive factor for real-world energy efficiency and long-term performance integrity.

Engineered Particle Geometry: The Core Innovation

These results are not incidental; they are the direct outcome of innovation in particle architecture. The advanced silicate at the heart of this performance, Hypertherm, is characterized by a high aspect-ratio morphology and an optimized, proprietary particle size distribution. This represents a significant leap from conventional fillers.

This engineered geometry enables advanced particle packing within the coating film. Think of it as the difference between a haphazard pile of stones and a perfectly interlocked stone wall. The resulting film exhibits markedly reduced porosity and significantly enhanced density. This nano-scale architecture delivers a powerful triad of benefits:

- Superior Thermal Resistance: Creates a more tortuous path for thermal energy, directly accounting for the dramatic slowdown in heat penetration.

- Enhanced Mechanical Strength: Forms a robust, cohesive scaffold that improves film integrity, scrub resistance, and overall durability.

- Excellent Opacity and Coverage: Provides superior light scattering from the particle geometry itself, leading to exceptional hiding power, a uniform finish, and improved formulation efficiency.

Achieving this multi-vector performance from a single additive platform is a hallmark of sophisticated, research-driven development. It reflects a deep understanding of how nano-scale properties govern macro-scale performance.

The Formulator’s Advantage in a Data-Driven Market

For the industry, this shift is transformative. It moves formulation from art toward predictive science, powered by additives that offer built-in, quantifiable advantages. The market increasingly demands this evidence, and the ability to integrate such engineered materials provides a clear competitive edge.

Companies at the forefront of this change, like 20 Microns Nano, are distinguished by their commitment to this depth of R&D. Their focus on engineered particle solutions—moving beyond commodity supply to creating performance-defining architectures—is what enables breakthroughs like the advanced silicate discussed here. It’s a model where investment in fundamental science yields tools that allow formulators to meet and exceed the most stringent performance benchmarks.

The future of high-performance coatings is being written at the particle level. It is a future built on engineered geometry, validated by uncompromising data, and realized through partnerships with innovators who provide not just materials, but the material science necessary to lead. For formulators, this isn’t just a new additive—it’s the new foundation for building better.

#CoolCoatings #ThermalManagement #EngineeredSilicates #AdvancedMaterials #MaterialScience #ParticleEngineering #Nanotechnology #CoatingInnovation #CoatingPerformance #EnergyEfficientCoatings #HighPerformanceCoatings#ConstructionTechnology #BuildingMaterials #SustainableBuildings #GreenTechnology #EnergyEfficiency #InfraTech #SmartMaterials#20Microns #20MicronsNano #RAndD #InnovationDriven #ManufacturingInnovation #FutureOfCoatings#SurfaceCoatings #PaintIndustry #IndustrialCoatings #ExteriorCoatings #ProtectiveCoatings #ThermalBarrier