In a world where supply chains are constantly tested, industries are looking beyond simple swaps to build real resilience. For manufacturers who have long depended on titanium dioxide (TiO₂) for whiteness and opacity, this presents a unique opportunity. The goal is no longer just to find an alternative but to use this challenge as a catalyst for smarter, more innovative product design.

The Smarter Approach: Working with What You Have

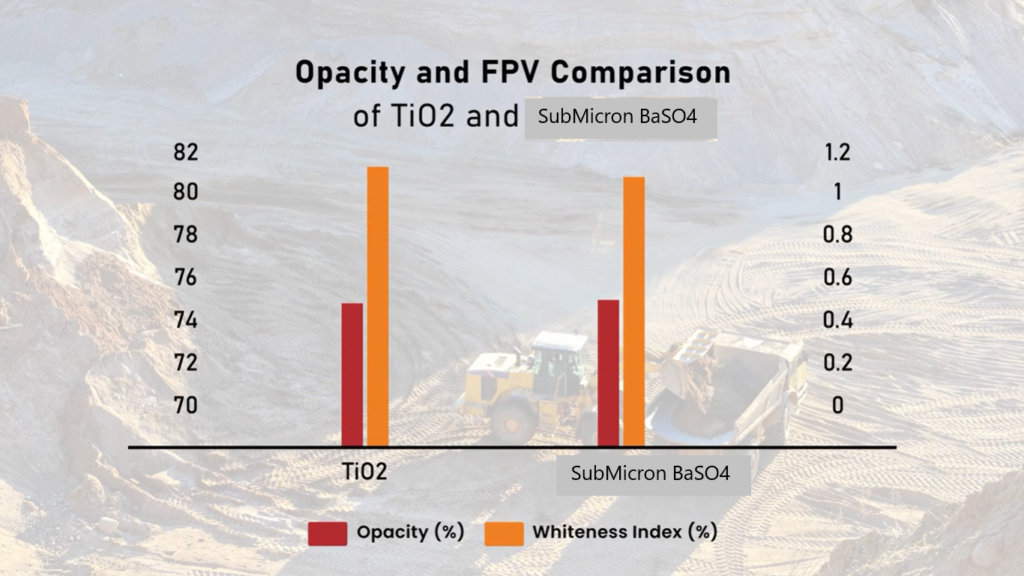

The most effective strategy isn’t about replacing TiO₂ entirely. Instead, forward-thinking companies are enhancing its performance with specialized additives. By integrating high-performance materials like submicron barium sulfate into their formulations, manufacturers can achieve the same excellent results—brightness, opacity, gloss—while using significantly less TiO₂. This approach directly tackles cost pressures and supply chain concerns without compromising on the quality your customers expect.

Building a Better Product, Not Just a Cheaper One

True innovation creates multiple wins. When done right, partial substitution does more than just reduce reliance on a single material. It can actually improve the final product. Benefits often include:

* A smoother, higher-gloss finish.

* Improved strength and durability of the plastic or coating.

* More vibrant and consistent colour.

* Greater stability during processing.

This turns a supply chain necessity into a tangible competitive advantage, offering enhanced value to the end-user.

The Path Forward: Partnering for Expertise

Navigating this shift requires expertise. Success depends on precise knowledge of particle science and formulation chemistry to ensure the additive works in perfect harmony with the TiO₂ and the base polymer. This is where specialized knowledge becomes critical.

Companies like 20 Microns Nano have built their focus on this precise area of innovation. By developing advanced solutions that enable efficient TiO₂ reduction, they provide the technical partnership manufacturers need to reformulate with confidence. Their work exemplifies how deep, application-specific R&D can solve broad industrial challenges, helping build strategic autonomy and a more resilient future.

The journey toward supply chain resilience is ultimately a journey toward innovation. By reimagining material use at a fundamental level, manufacturers can build stronger businesses and better products.

#MaterialsInnovation #AdvancedMaterials #SupplyChainResilience #SmartSubstitution #TiO2 #FormulationScience #SpecialtyChemicals #IndustrialInnovation #CoatingsIndustry #PlasticsIndustry #20microns #20micronsnano