While design and technology capture attention, a transformative manufacturing process works behind the scenes: Powder Metallurgy (PM). It is fundamental to making vehicles stronger, lighter, and more efficient. The automotive industry is its primary driver, consuming the majority of the world’s metal powder.

What is Powder Metallurgy?

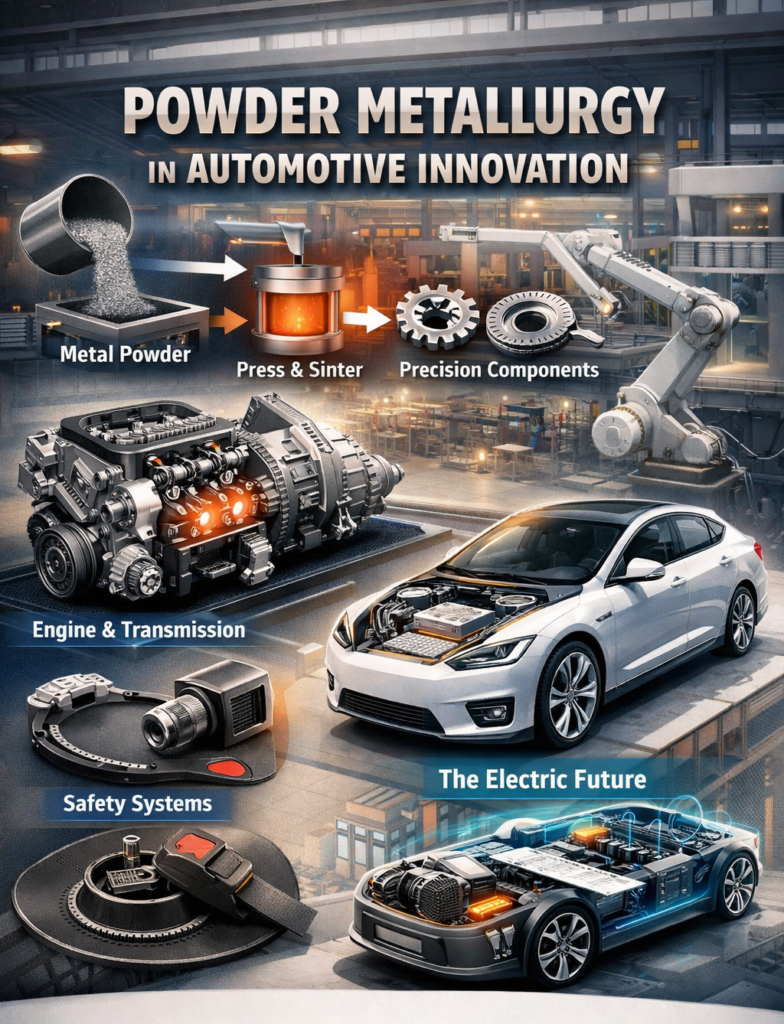

Imagine building a metal component from the ground up instead of cutting it from a solid block. PM begins with fine metal powder, akin to flour. This powder is compressed in a precision mold under immense pressure and then fused together with heat. The advantages are significant: near-zero material waste, the capacity to form highly complex, net-shape parts, and unmatched consistency for mass production.

Indispensable Automotive Applications

PM components are ubiquitous, found from the engine to the wheels.

* Engine & Transmission: Here, PM proves its durability. Critical parts like connecting rods, main bearing caps, and camshaft phasers are formed via PM to endure extreme heat and pressure cycles. The process creates intricate internal features, like oil passages, that enhance performance and longevity. In transmissions, PM produces robust yet lightweight planetary gear carriers and synchronizer hubs, contributing directly to smoother operation and fuel efficiency.

* Safety Systems: Where failure is not an option, PM delivers absolute reliability. Essential components such as Anti-lock Braking System (ABS) sensor rings are precision PM parts. Elements within electronic power steering and seat belt mechanisms also rely on the material integrity and consistency that only PM can guarantee at scale.

* The Electric Future: The shift to EVs accelerates PM’s importance. It is crucial for manufacturing soft magnetic composites (SMCs) used in electric motor stators and rotors, improving power density and efficiency. PM is also deployed for thermal management components in battery packs and electromagnetic shielding. As EVs demand compact, high-performance solutions, PM’s ability to create complex, multi-functional parts makes it essential.

The Indian Opportunity: A Market Poised for Accelerated Adoption

The foundational role of PM creates a vital opportunity, particularly in high-growth markets like India. While India’s automotive sector is massive, its use of PM—at about ~7 kg per passenger car—remains a fraction of the 15-20 kg used in vehicles from mature markets like the U.S. and Europe. This significant gap is not a weakness, but a clear indicator of immense potential. As the Indian automotive industry rapidly evolves—moving towards heavier vehicles, more advanced features, and electrification—the demand for sophisticated PM components is set to surge. The shift to EVs, in particular, will be a powerful catalyst, driving the adoption of PM for electric motors, power electronics, and lightweight structural parts.

The Foundation of Future Mobility

The automotive industry’s evolution toward electrification and autonomy amplifies the need for PM. This advanced manufacturing is not a legacy technique but a foundational technology for next-generation mobility.

This creates a vital opportunity. The entire automotive value chain depends on a critical upstream link: the advanced metal powders that enable this process. The global metal powder market, valued at over $6 billion in 2023 and projected for strong growth, is a direct beneficiary of this trend, with India’s market emerging as a high-growth segment poised to bridge the “kg-per-car” gap.

This ecosystem includes global listed leaders like Höganäs and GKN Powder Metallurgy. In India, a specialized and competitive player like Innomet Advanced Materials is emerging (which notably also supplies to Höganäs and Sundaram Fasteners). They provide the essential, high-performance foundation that empowers engineering innovation, enabling the strength, efficiency, and breakthroughs the market demands.

For forward-thinking investors, this reveals a strategic opportunity. The most compelling growth in automotive is increasingly found in the enabling supply chain. Investing in the leading providers of these fundamental materials—companies characterized by precision, technical expertise, and deep partnership—is an investment in the very infrastructure of the automotive future, especially in markets like India where adoption is accelerating from a robust baseline. It represents a sector where innovation and quality drive sustained growth.

Disclosure: WisdomIR advice Innomet Advanced Materials on IR